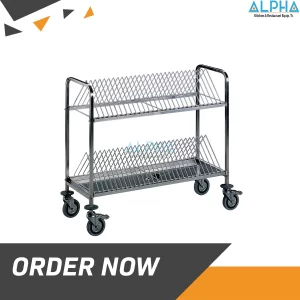

Defrosting Trolley

This defrosting trolley is a hygienic stainless steel solution designed for controlled thawing of frozen food in professional kitchens, therefore reducing drip mess and improving food safety workflow.

Technical Specifications

| Product Type | Food Defrosting / Thawing Trolley |

| Material Grade | Stainless Steel AISI 304 |

| Top / Tray Design | Perforated tray / removable grid to separate food from drip |

| Drainage | Drain outlet + valve (size: 15mm) |

| Capacity | ( GN capacity / tray count) |

| Mobility | 4 swivel castors (2 with brakes) (confirm) |

| Dimensions (L×W×H) | ( 1000×546×130) |

| Finish | Brushed / Satin finish |

Custom sizes, drain positions, and tray configuration available on request.

Key Benefits

✔ Cleaner thawing with controlled drip collection

📍 Hygienic stainless steel build for food areas

✔ Faster workflow, therefore less handling time

📍 Easy movement between prep, cold room, and wash

✔ Removable parts support daily cleaning

📍 Custom fabrication available for your kitchen layout

Features and Benefits

- Designed to manage thawing liquids and reduce floor contamination.

- Helps separate food from drip, therefore improving hygiene control.

- Mobile design supports better workflow between stations.

- Easy-to-clean surfaces support HACCP-style routines.

- Custom dimensions available to match your tray system and space.

Best For

- Hotels and high-volume restaurants

- Central kitchens and catering operations

- Butchery and meat preparation areas

- Seafood handling and prep rooms

- Food factories and institutional kitchens

Applications

✔ Meat thawing

📍 Seafood thawing

✔ Poultry thawing

✔ Batch prep workflow

📍 Cold room operations

✔ Hygiene-controlled handling

Frequently Asked Questions

What is a defrosting trolley used for?

It is used to thaw frozen food while collecting drip safely, therefore keeping prep areas cleaner and more hygienic.

Does it include a drain outlet and valve?

Many designs include a drain outlet and valve for easy emptying. Confirm your required outlet size and position before fabrication.

Can you fabricate custom sizes?

Yes. Custom dimensions, tray configuration, and drain position can be made to match your kitchen workflow.

Is stainless steel 304 recommended for this product?

In most food environments, 304 is preferred for hygiene and corrosion resistance. If you work with aggressive cleaning chemicals or high salinity, consider 316.

How do I clean it properly?

Remove the tray/grid, wash with approved food-safe detergent, rinse, and dry. Clean the drain path daily to prevent odour and residue build-up.

Shipping and Warranty

- Delivery available across UAE (Dubai, Sharjah, Ajman, Abu Dhabi).

- Custom fabrication lead time depends on size, material grade, and quantity.

- Warranty is provided against manufacturing defects (terms confirmed with quotation)